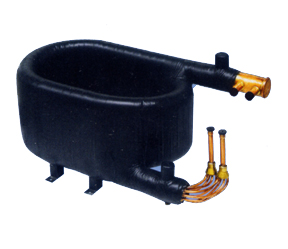

| The

heat exchanging tubes are tube bundles with riffled tube and outer tubes are seamless

steel tubes covered with thermal insulation materials. The refrigerant evaporates

through forced convection in the heat exchanging tubes and cools the tube walls.

The circulating water flows outside the tube bundles and heats the tube walls

through forced convection. The two medium exchanges heat via walls of the heat

exchanging tubes. In established utilization scope, flows on both sides of the

tube walls are vigorous turbulent flows.

The

heat exchanging tube bundles are symmetrically distributed into a helical structure

of specific thread intervals. Such a structure enables the tube pass length, serviceable

conditions, reliability, and heat-exchanging boundary situations of all tubes

are the same. In addition, under the co-function of helical tubes and the inner

threads, secondary circulation flows in vertical direction to the main flow are

formed in the tubes. Complicated irregular channels with helical features are

formed in the intervals between the helical tube bundles and outer tube cases.

As a result, powerful secondary circulating flows are formed from the circulation

water. The secondary circulation flows on both sides prominently strengthen the

heat exchanging effects. Liquid

distributors are installed in the refrigerant inlet to ensure that the flow supply

to each tube pass is even and uniform, so as to make full use of the heat exchanging

surface. |

|  The series of screw coaxial heat exchangers have

the following features: The series of screw coaxial heat exchangers have

the following features:

1. Rational structure and outstanding performance

The SCE series of screw coaxial heat exchangers have been designed on the basis

of summarizing the existing domestic and overseas designing experiences and after

lots of simulation calculations and dissection experiments. The designs are comprehensively

optimized, the structure is more rational, and the performances are even better.

2. Using choice materials and with reliable

functions

Quality copper tubes with riffled threads and low ribs up to

GB/T8890-1998 are chosen as heat exchanging tubes. As for the outer casing tubes,

quality seamless liquid tubes with smooth inner walls, up to GB/T8163-1987 are

chosen and processed with hot galvanizing techniques. Compared with weld steel

tubes, seamless tubes do not involve the risk of welding seam breaking from the

vibrations and pressure impacts during long period of operations and the risks

of the copper tubes' being punctured by burrs on the inner walls of the seams.

Therefore, its long-term service is highly reliable. 3. Pressure and vibration resistance and low

deforming risks

In the practical operations of refrigeration systems,

influenced by temperature fluctuations, circulation starting and stopping, the

heating pumps' defrosting, and expansion valve adjustments, the internal pressure

is always under frequent alterations. Under high or frequently changing pressure,

plate heat exchangers are liable to deform, fatigue, and be damaged. But coaxial

round pipe structure is much more capable in terms of high pressure and impact

resistance. Therefore, screw coaxial heat exchangers can better suit the complicated

practical operation situations of refrigeration systems. 4. Dirt and clog resistant

As screw

coaxial heat exchangers' side water flow passages are of large sections and facilitate

the passing of large fibers and sands in the water, the passages are unlikely

to be clogged. For the same reason, scale deposits forming on the tube walls from

hard water are unlikely to cause clogs. Therefore, screw coaxial heat exchangers

have strong water quality permission range. 5. Unhindered lubricant circulation and high

security

There is no upright ascending passage in the refrigerant flowing

process of screw coaxial heat exchangers and even if the flow is small, the lubricant

can surely return to the compressor. It is unnecessary to worry about such risks

as reduction in heat exchanging area, passage clogging, instability in operation,

and damages to the compressor because of lubricant blocking in the evaporators.

6. Top techniques and little leakage risk

During

the manufacturing process of screw coaxial heat exchangers, it is only necessary

to connect a few places at the entrances and exits of tubes and the connecting

techniques are far simpler and easier than those on other heat exchangers. It

is easy to guarantee the connecting quality and control the risks of leakage at

connecting points from long term of vibrations, fluctuating pressure, and temperature

alterations. 7. Flexible structure and convenient to collocate

screw coaxial heat exchangers have unique advantages in terms of structure

flexibility because the outer tubes can almost be processed into any shape according

to the users' needs and so are the locations and directions of outlet and inlet

tubes. Although the tubes may occupy a large area, as they are hollow inside,

other parts of the system can be placed here. Besides, at more and more occasions,

the users request the heights of heat exchangers be lowered as much as possible

and screw coaxial heat exchangers can perfectly meet the users' designing requests. 8. Low price and cost effectiveness

As

it is unnecessary to use a lot of such expensive metal as stainless steel and

aluminum and complicated manufacturing techniques, the users are able to purchase

heat exchangers of the same capacity at lower prices and the manufacturing costs

of whole units can be effectively decreased. Additionally, as screw coaxial heat

exchangers wear well, they can help the whole unit manufacturers save large amount

of after-sales service expenses. 9. The products can be of multiple circuits

According

to the clients' requests, this product can be built into heat exchangers of single

water circuit, two freon circuits, or multiple freon circuits to satisfy the requirements

of multiple system mainframes, perform energy adjustment, and meet the society's

current needs for energy saving. |